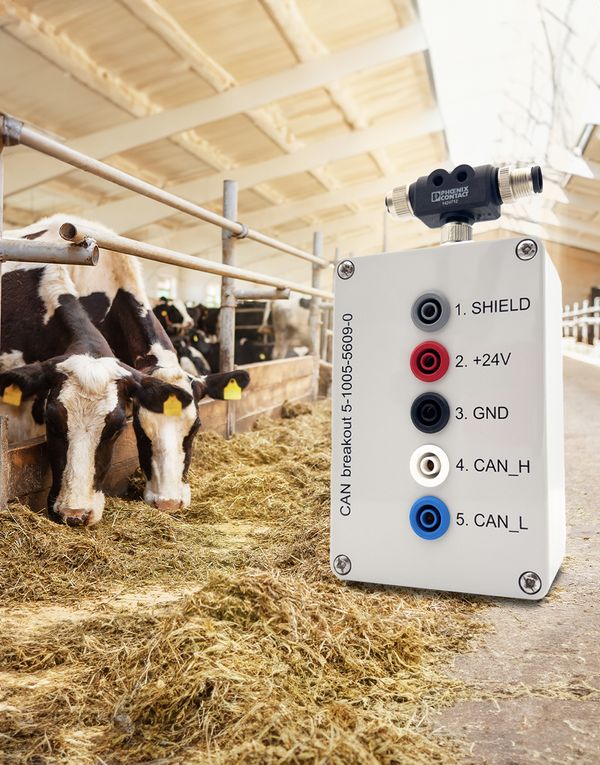

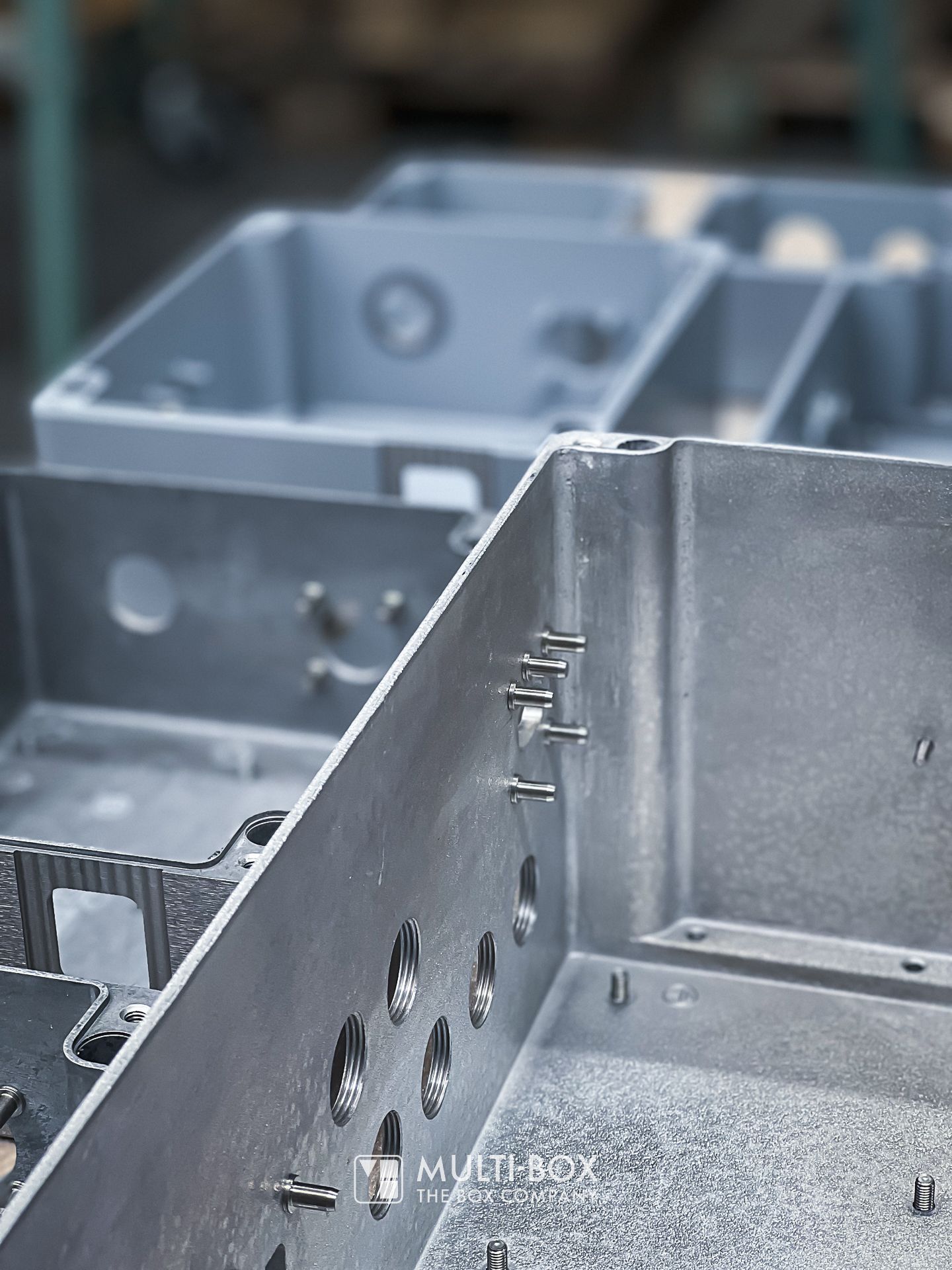

Our enclosures offer various fixing points in the base as standard. Here you can directly assemble components such as DIN rails, PCBs or mounting plates.

- 1. Plastic enclosures offer domes for fastening with self-forming plastic screws.

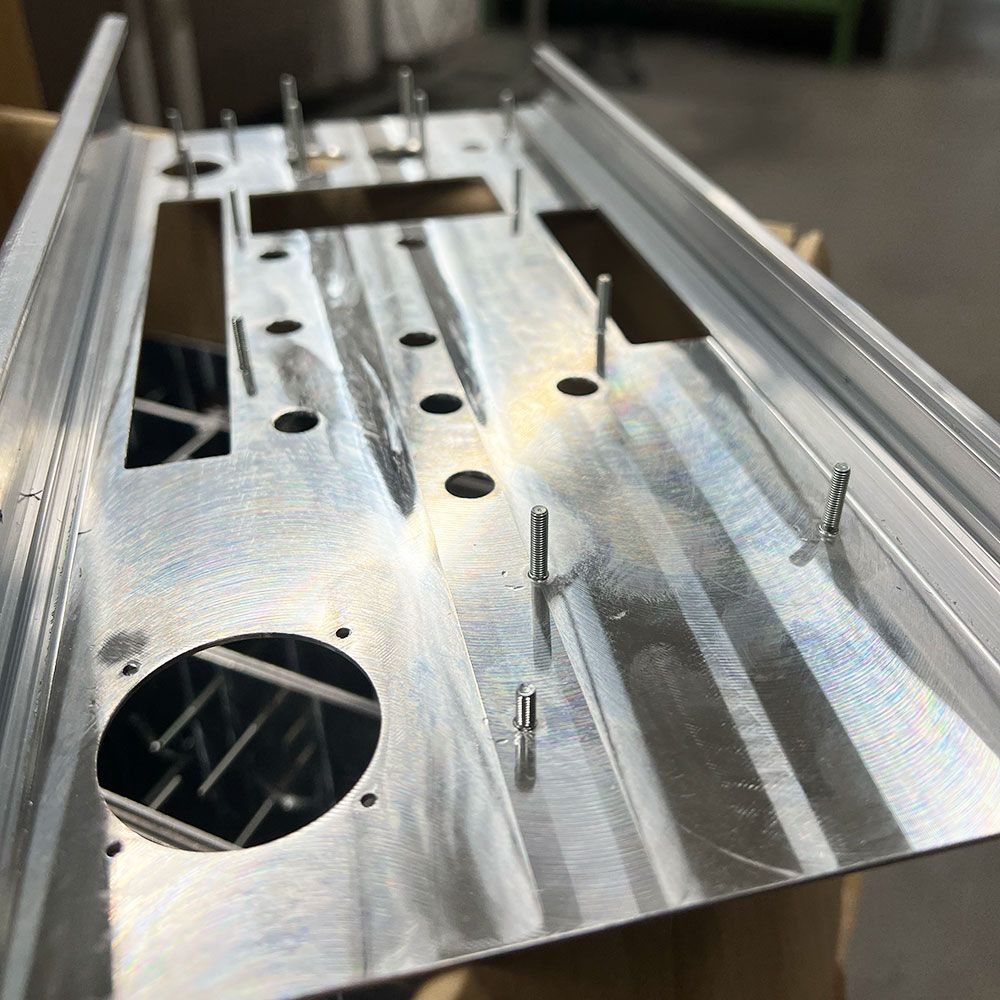

- 2. Aluminium enclosures offer mounting bars with metric threads for standard screws.

But what if the standard fastening options in the enclosure are not suitable for mounting your components?

With our PEMSERTER-4 press, we can press in various fastening elements into our enclosures. You can individually specify the number and position.

The additional fasteners can be inserted into aluminium, plastic and polyester enclosures. They are available in various materials, thread types and lengths, depending on the application.

The fastening elements can be inserted into the cover, the base and also on the side walls of the enclosure. This allows you to make optimal use of the available installation space. The enclosures retain their protection class despite the additional fixing points.

What does it look like?

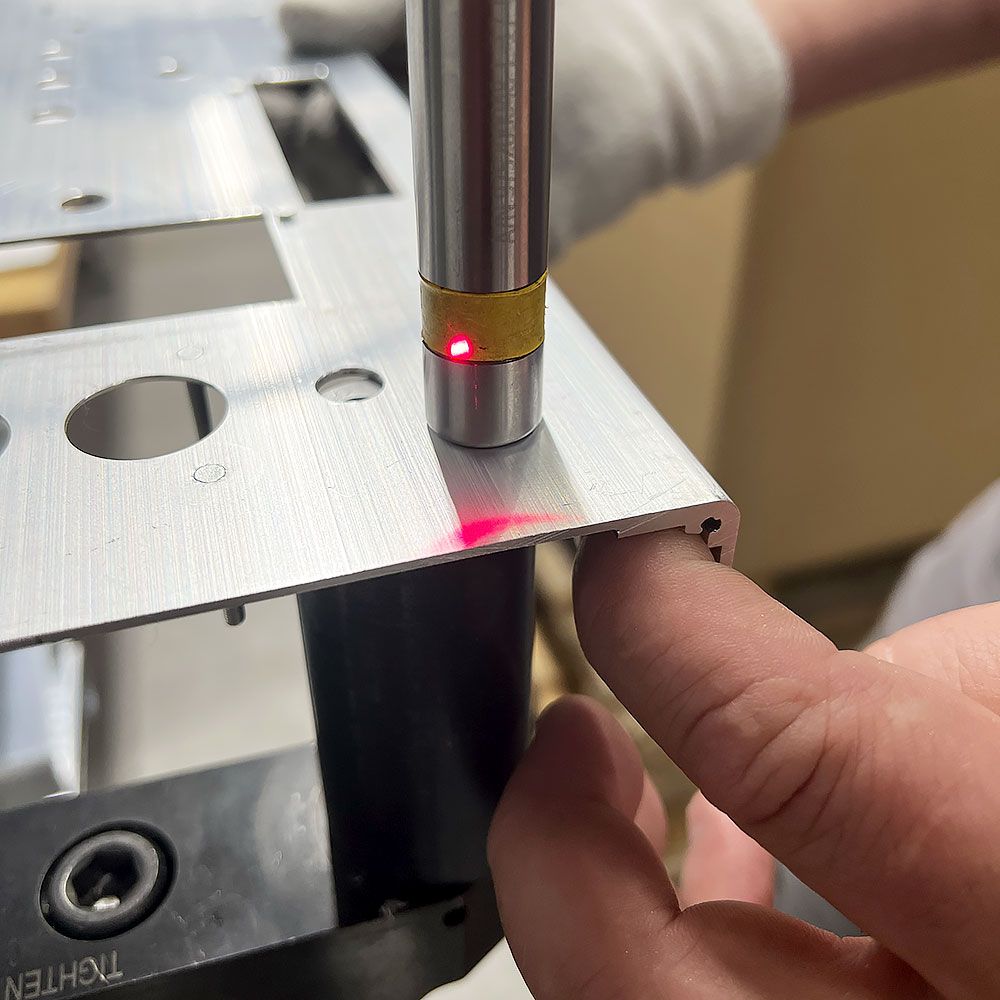

How does it work?

- In the first step, the mounting holes or recesses for the respective fasteners are milled into the enclosure wall using a CNC machine. Precision is required here, because the correct fit and strength of the fixing element depends on the accuracy of the milling.

- With the help of our press, the elements are inserted into the pre-milled mounting holes in the enclosure. In this process, the enclosure material bonds with the fastening element through cold deformation. A special toothing system on the insert prevents from twisting and ensures a very strong hold.

- After pressing in, the fastening elements are flush with the enclosure surface. For aluminium enclosures, the fastening elements are preferably inserted into the unpainted parts. This way, the fastener heads are almost invisible after powder coating.