The current situation on the energy market is forcing private households and many industrial companies to rethink.

No one can foresee how the situation will develop but one thing is clear: We are facing fundamental changes and renewable energies are moving even more into focus. Besides security of supply, the carbon footprint is an important issue for modern production companies.

With the idea of being able to produce more economically and ecologically, we installed our PV system with a total area of approx. 3,000m² and a peak output of 338 KW in October 2020.

Today, we can keep our production running self-sufficiently temporarily under optimal conditions. To turn "temporarily" into much more, we are planning a significant expansion of our PV system with the current construction of our new production hall.

Facts about our PV system

Enclosures solution for the PV market

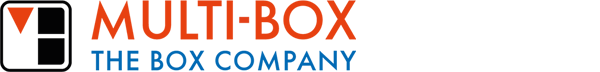

The market for renewable energies is growing rapidly and many of our customers come from this industry. This means that the demand for suitable enclosures is also increasing. We have thought about this and finally developed our new MBI enclosure program.

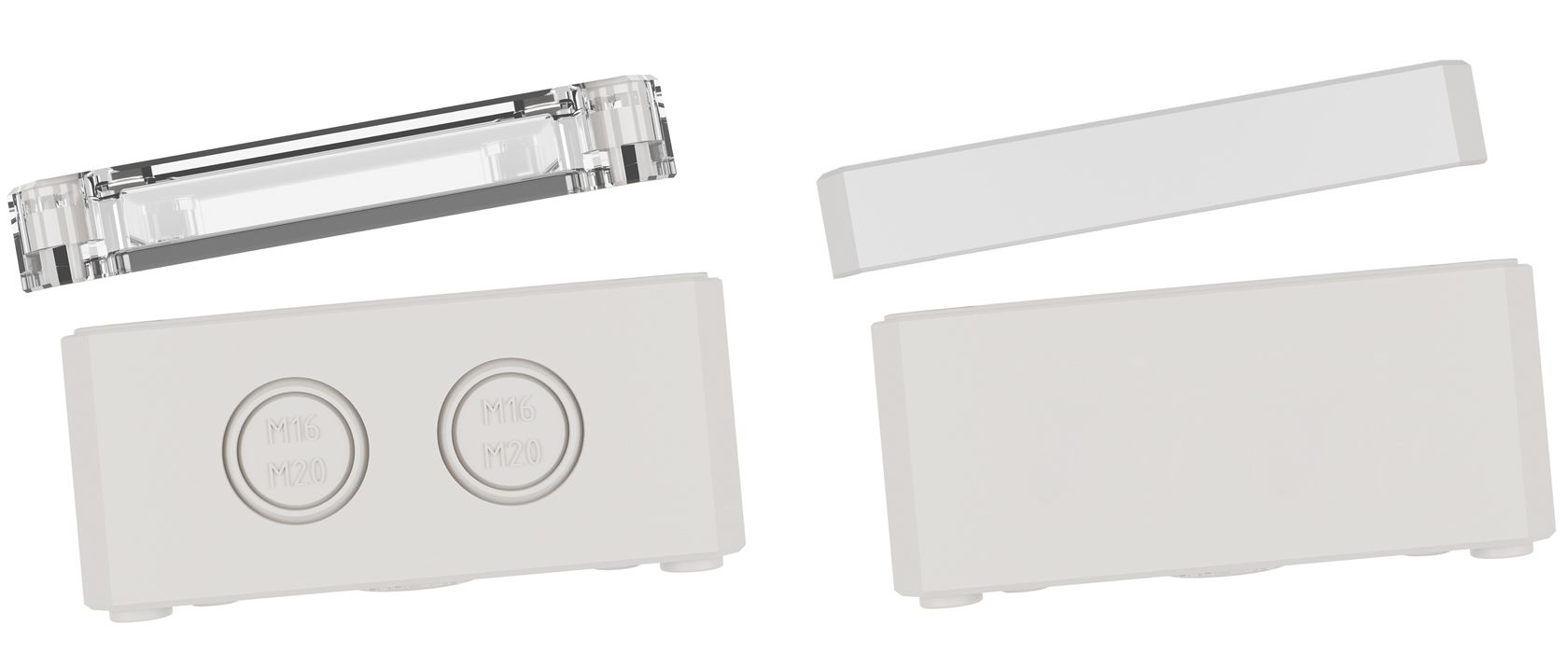

While MB stands for MULTI-BOX, the I stands for "Intelligent. Industrial. Installation". MBI enclosures are characterised by a wide range of sizes and a systematic focus on requirements in industrial installations. The base parts of the enclosures are optionally available with metric pre-formed knockouts or plain side walls. They can be combined with grey or transparent covers.

KEY FEATURES

- Systematic focus on requirements in industrial installations

- Suitable for use in industrial and outdoor applications

- Enclosure bases with metric pre-formed knockouts or plain side walls

- Individual side designs with mould inserts on demand

- Corrosion-free plastic cover screws

- Variety of fastening points in the base of the enclosure

- Various fastening options on walls or machines

- Production in special colours on request

- Completely recyclable 🌱

TECHNICAL SPECIFICATIONS

- Protection class IP66

- Seamlessly foamed-in 2-component polyurethane gasket

- Impact resistance IK08 (DIN EN 50102:1997-09)

- Glass-fibre reinforced polycarbonate in colour grey RAL 7035

- UV-resistant (UL 746C F1)

- Self-extinguishing (UL 94 V0) in colour grey

- Flammability classification UL 94 V2 with transparent cover

Depending on quantities, we can produce customer-specific mould sides. Individual knockouts, cutouts and hole designs can be implemented in the injection mould and there is no requirement for further mechanical processing.

Further information as well as possible sizes and technical drawings can be found on our website. If you want to convince yourself of the product quality, you are welcome to request a sample.