Depending on the application area, our enclosures are available in various protection classes between IP54 and IP69. But which level of protection is the right choice for your product? Many of our customers are uncertain. For this reason, we would like to introduce you to the topic of "classification of protection classes for enclosures" with this article.

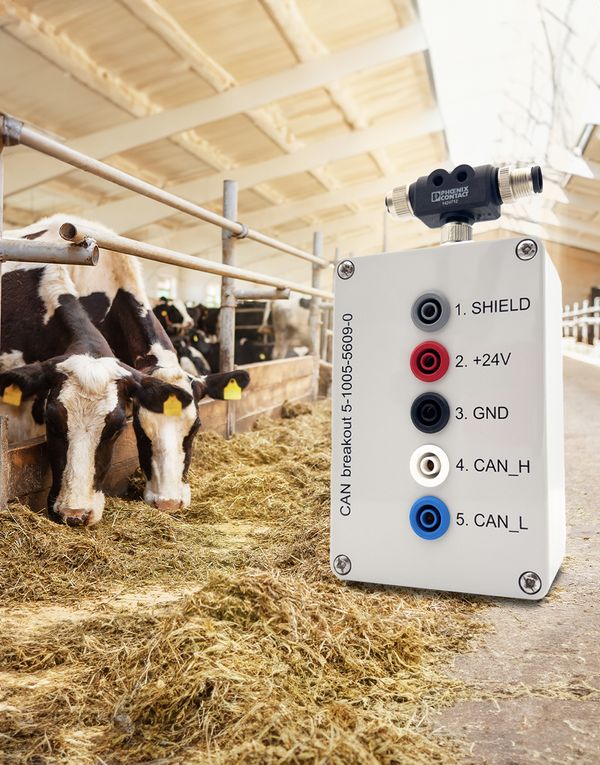

When talking about "testing the protection class of an enclosure" you might think of something like this.

We have to admit: Testing in the laboratory is slightly less spectacular. However, the result of our firefighting mission is very interesting. Of course, our MBX-PRO enclosure was absolutely tight!

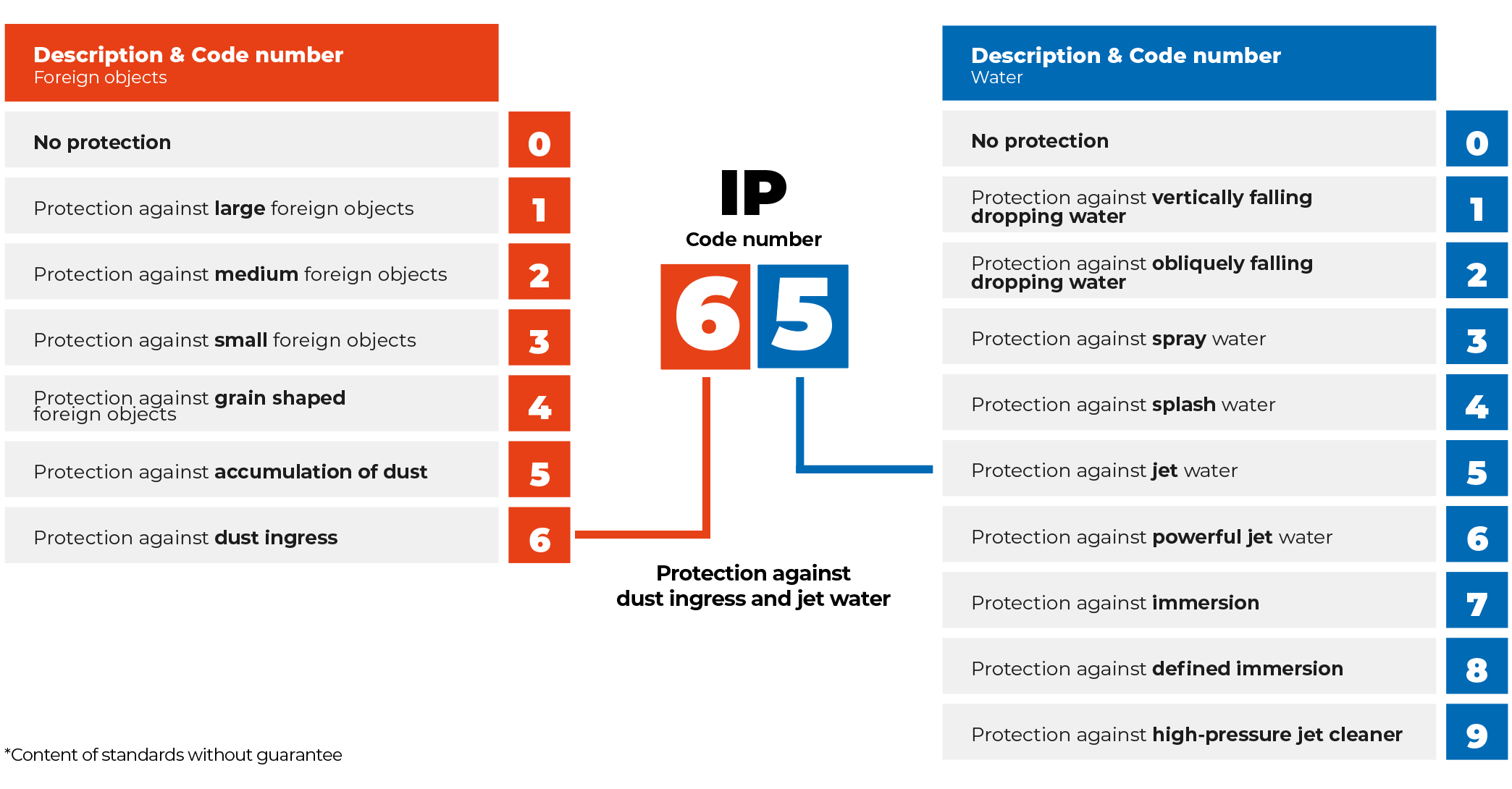

What are IP protection classes and what do they indicate?

The protection class indicates the suitability of electrical equipment and components for various environmental conditions. In addition, it describes the degree of protection for people against potential dangers during their use.

The classification in IP protection classes defines how strongly an enclosure is protected against the ingress of water and foreign objects, such as dirt and dust.

The so-called IP code means "Ingress Protection". The degrees of protection are regulated in ISO 20653 or DIN EN 60529 and consist of 2 code digits.

How do we test our enclosures?

Trust is good, control is better - best in our own laboratory

Absolute reliability and permanent protection of installed components against harmful environmental influences are the focus of our daily work. In order to ensure that our enclosures deliver what we promise, we test them for their future tasks. In addition, we also test individualised enclosure solutions including built-in electronics for our customers. We carry out the following tests in our in-house laboratory:

IP dust protection test

(DIN EN 60529)

For the dust protection test in accordance with protection classes IP5X and IP6X enclosures are tested in a dust chamber for a defined period of time. A vacuum is created inside the enclosure, with talcum powder constantly stirred up within the test chamber. The enclosure is opened after the test cycle and no talcum powder must have penetrated, despite the negative pressure generated.

Protection class IP5X:

- Vacuum: with or without 20 mbar

- Test duration: 8 hours

Protection class IP6X:

- Vacuum: with 20 mbar

- Test duration: 8 hours

IP water protection test

(DIN EN 60529)

For the water protection test according to IP X5, X6, X7, X8 and X9K the enclosure is tested using our test systems according to the defined parameters. We regulate the water temperature and can install different nozzles to control the water flow and water pressure. For our customers, we test fully installed products to avoid failures due to water ingress.

Protection class IPX5:

- Protection against jet water

-️ Test with jet nozzle Ø = 6.3 mm

-️ Water flow rate: 12 l/min

-️ Water pressure: 30 kPa

-️ Water temperature: Difference not more than 5°C to the enclosure

-️ Distance between enclosure surface and water nozzle: 2.5 - 3.0 m

-️ Test duration: 3 min.

Protection class IPX6:

- Protection against jet water

- Test with jet nozzle Ø = 12.5 mm

- Water flow rate: 95 - 105 l/min

- Water pressure: 100 kPa

- Water temperature: Difference not more than 5°C to the enclosure

- Distance between enclosure surface and water nozzle: 2.5 - 3.0 m

- Test duration: 3 min.

Protection class IPX7:

- Protection against temporary immersion in water

- Test by complete immersion

- Deepest point of the enclosure 1 m below the water surface

- Water temperature: Difference not more than 5°C to the enclosure

- Test duration: 30 min.

Protection class IPX8:

- Immersion protection for a defined time and depth

- Test by complete immersion

- Deepest point of the enclosure *defined depth under the water surface

- Water temperature: Difference not more than 5°C to the enclosure

- Test duration: *defined time

Protection class IPX9:

- Protection against hot high pressure jet water

- Testing with high pressure nozzle at an angle of 0°, 30°, 60°, 90°

- Distance between enclosure surface and water nozzle: 150 - 200 mm

- Enclosure mounted on a rotating table with 5 rpm

- Water flow rate: 14 - 16 l/min

- Water pressure: 0,9 - 1,2 N

- Water temperature: 75 - 85 °C

- Test duration: 30 sec./side

Important notes on classification of protection classes

- Indicated protection classes always refer to unmachined standard enclosures

- For protection against water (second code number), the tests are passed if no water or water in a non-harmful quantity has ingressed during the specified time

- Protection class testing does not consider ageing. Thus, the maintenance of the protection class over the entire life of the product is not guaranteed

- Temperature changes that can occur outdoors are not covered by the protection class tests

- Strong temperature changes can lead to negative pressure inside the enclosure, causing moisture to be pulled inside through the sealing. We recommend the use of pressure compensation elements

- For the first code number (protection against foreign objects) a defined degree of protection of the enclosure automatically includes all lower degrees of protection

- For the second code number (protection against water) a defined degree of protection of the enclosure does not include all lower degrees of protection

- Up to code number X6, all lower degrees of protection are also fulfilled

- An enclosure with code number X7, X8 (protection against submersion) or X9 (protection against high pressure water jets) does not automatically imply a lower degree of protection. In this case, the information refers solely to the code number indicated. Only when an enclosure has a double marking it fulfils both requirements.

#morethanboxes #ip #protectionclass #ip69 #ip66 #ip65 #multibox #box #enclosures