The HURCO VM1 machining centre has been in use since 2005. A consistently reliable machine which has realised many projects over the years. Mainly aluminium enclosures MBA were machined according to individual customer drawings.

With a running time of over 30.000 hours, which corresponds to approx. 7 million M16 threads, we are now sending the machine into a well-deserved retirement.

When we bought the VM1 back in 2005, it was state of the art. It had advanced features that allowed us to work more efficiently and precisely. The years went by and despite its age, the machine remained a valuable benefit to our company for a long time and was in continuous and tireless use until the end.

Turn old into NEW ✨

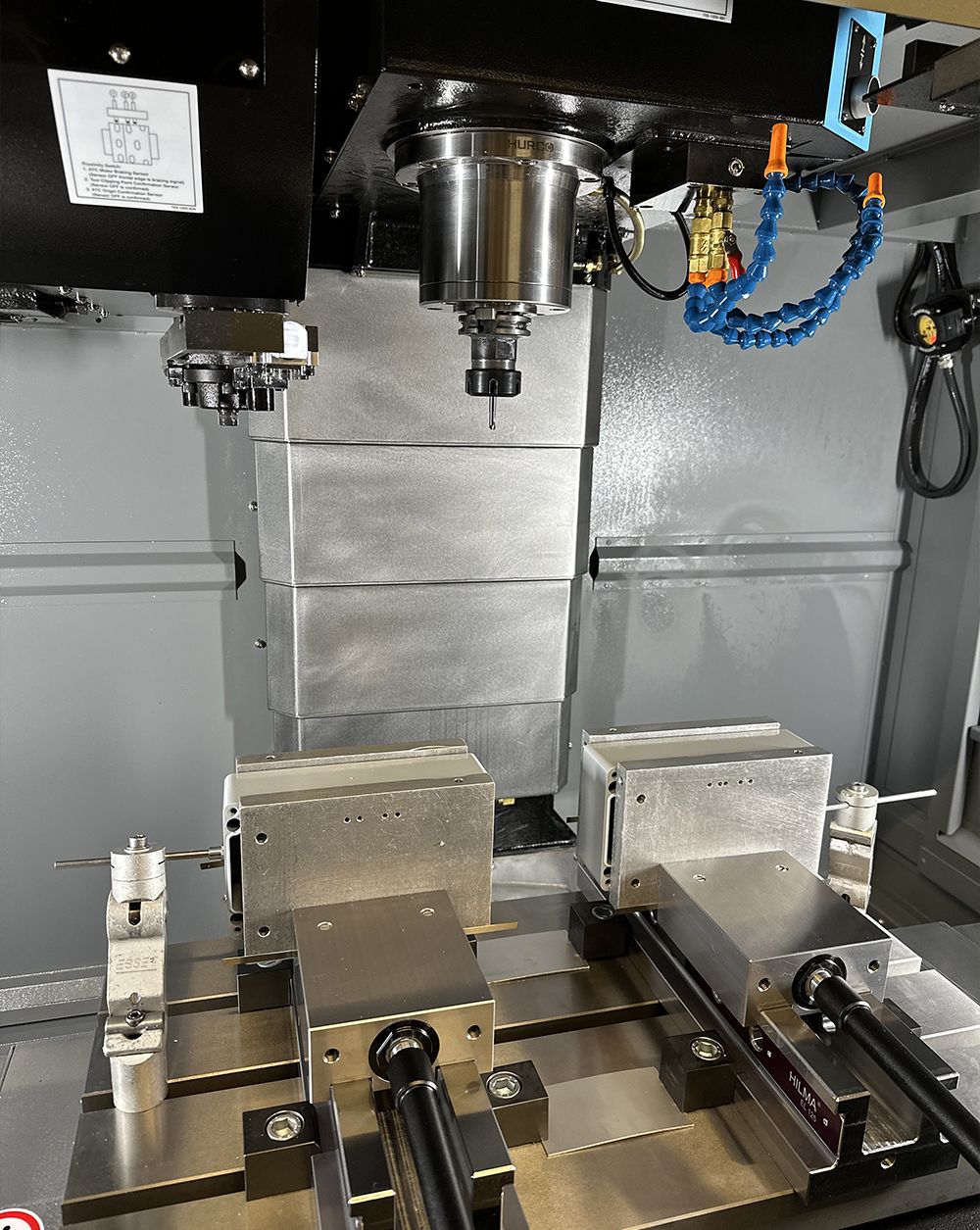

May we introduce: Our new HURCO VM10i Plus!

The decision to buy this machine was made because we can machine almost the same range of enclosures with the axis movements as we could with the old VM1. But of course there is much more...

What makes the new machine better than the old one?

- With the built-in probe sensor, the machine can automatically measure the components before machining. This is an advantage especially when milling more complicated engravings or surfaces so we can guarantee consistent quality.

- Improved usability in programming thanks to the latest WinmaX control system.

- Integration of the machine into our network and central creation and management of the milling programmes.

- The machine works more accurately and at a higher speed.

- Furthermore, it simply looks much better and more modern. 😉

Although, all our enclosures are mould-related and come from corresponding tools there are always slight tolerances in the dimensions. Especially for aluminium enclosures, such tolerances arise due to the reworking process (grinding and barrel finishing) after casting. With the built-in probe sensor, the VM10i Plus can automatically measure each enclosure and ensure that the position of the required machining is always absolutely identical.

With the installation of the new HURCO VM10i Plus, the last machine without a network connection disappears from our mechanical production. This way, we ensure absolute data consistency and avoid potential errors due to outdated drawings.

Facts and figures

HURCO VM10i plus

Table

| Table working surface W x D (mm) | 762 x 406 |

| Load max. (uniform distribution) (kg) | 1500 |

Travels

| X-Axis | 660 mm |

| Y-Axis | 406 mm |

| Z-Axis | 508 mm |

Spindle

| Spindle Speed max. (rpm) | 10.000 (U/min) |

| Spindle Power (30min Rating) (kW) | 11 kW |

| Spindle Torque (30min Rating) (Nm) | 74 Nm |

Feedrates

| Rapid traverse X/Y/Z-Axis | 28 / 28 / 28 (m/min) |

Further details

| Floor space | 3.264 x 2.930 x 2.564 mm |

| Machine weight (kg) | 2.850 kg |

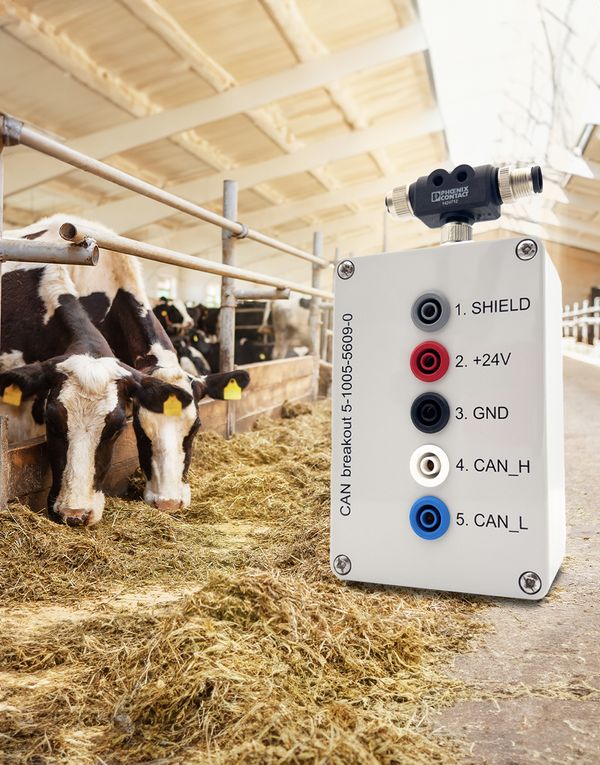

Mechanical processing of enclosures - individuality is our standard

With our extensive range of machines and a highly motivated team, we transform our standard products into your individual enclosure solution.