On safe rails into the future 🚄 Rail transport as a pillar of mobility

Safety and reliability of rail vehicles is of great importance economically and socially. Sustainable mobility, efficient freight transport and a switch from road to rail are hot topics that "move" us all.

From high-speed trains to automated rail systems or modern display technology in railway stations. Our industrial enclosures are used in many different applications.

What is the EN 45545-2 standard and how is it related to our enclosures?

The European standard EN 45545-2 describes the fire protection requirements for railway vehicles. It defines the demands on materials, components and systems with regard to their behaviour in the event of fire and harmonises existing standards in individual countries.

EN 45545-2 replaces following national standards

Overall, the standard aims to ensure the safety of passengers and staff in rail vehicles in the event of a fire and to minimise the risk of fires in such vehicles.

Following fire technology characteristics are tested for all installed components and therefore also for our enclosures (FIRST principles):

HL1, HL2 or HL3? - Which classes are defined and what do they indicate?

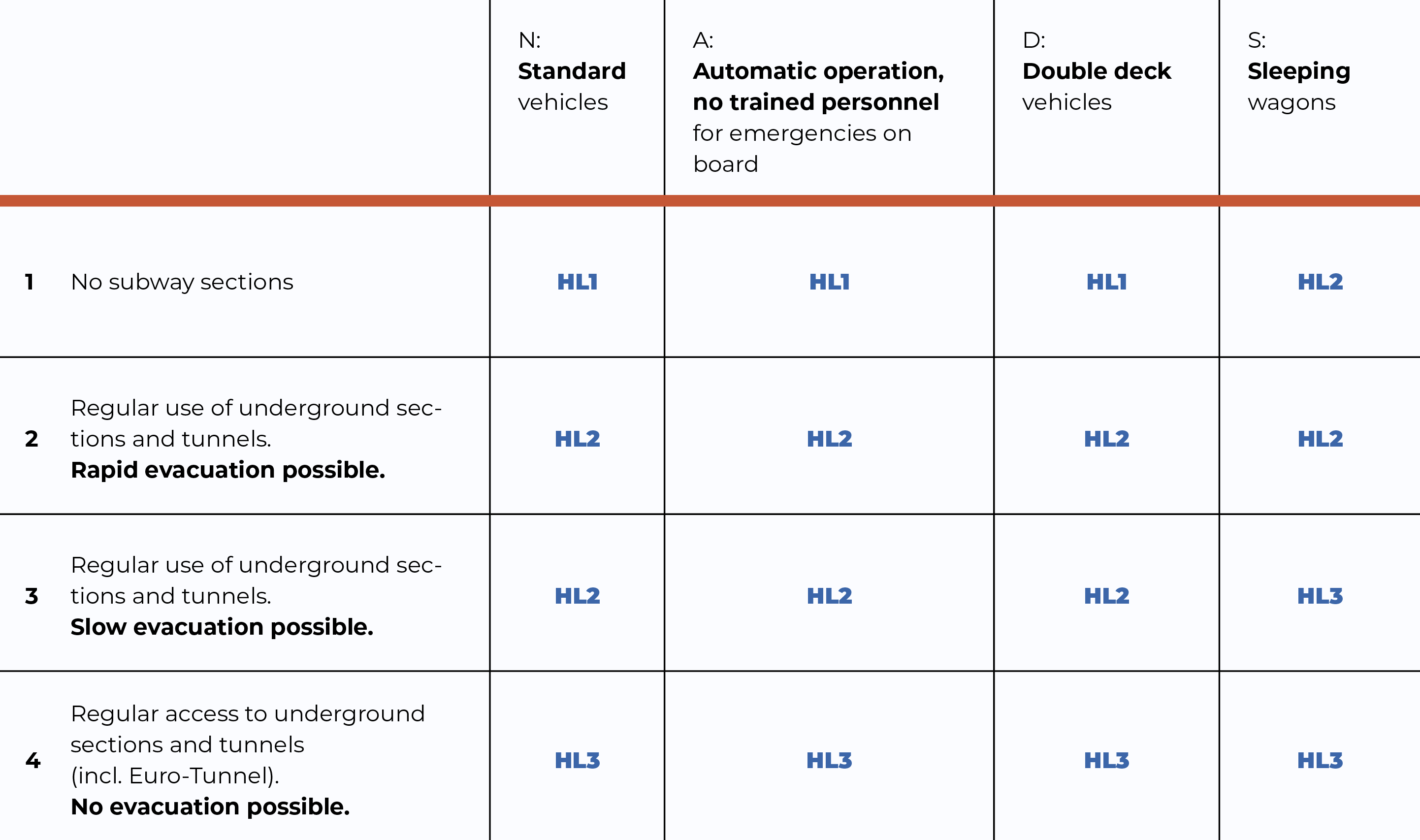

EN 45545-2 differentiates between various hazard levels and specifies so-called HL classes (Hazard Levels) for materials. To categorise materials into the corresponding hazard classes, the FIRST test methods contain specified limit values.

Specification of the required HL class for components depends on various factors:

- Type of rail vehicle

- Location where the rail vehicle is operated

- Positioning of the component in the vehicle

- Potential fire hazard of the component

Operating type and design category define the necessary hazard level

Exact classification and the associated requirements may vary depending on national regulations and laws. In general, DIN EN 45545-2 differentiates between following HL classes:

- HL1 (Hazard Level 1): This is the lowest hazard level in terms of fire safety. Hazard Level 1 materials are easier to ignite and can develop higher levels of smoke gases. They are normally used in less critical areas of railway vehicles.

- HL2 (Hazard Level 2): Medium Hazard Level 2 materials have higher fire safety requirements than HL1, but are still less fire-safe than HL3. They are used in areas of railway vehicles where fire safety is important, but not as critical as in passenger areas, for example.

- HL3 (Hazard Level 3): This is the highest hazard level. Hazard Level 3 materials are flame-retardant and produce minimal smoke gases in the event of fire.They are used in particularly sensitive areas of rail vehicles, such as sleeping wagons.

Which enclosures can we offer for railway applications with EN 45545-2 approval?

MULTI-BOX offers a wide range of enclosures suitable for railway applications in accordance with DIN EN 45545-2 to meet the various requirements of our customers.

Our railway enclosures are available in three different materials:

Each material has its own advantages and disadvantages, which should be carefully evaluated depending on the area of application. Here you will find an overview of the different material groups and their key characteristics and features:

Advantages & Disadvantages of the approved rail product groups:

| POLYCARBONATE (MBX) | POLYESTER (MBP) | ALUMINIUM (MBA) | |

| Chemical resistance | ⭐️⭐️ | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️ |

| Corrosion resistance | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️⭐️ | ⭐️⭐️ |

| Impact resistance | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️ | ⭐️⭐️⭐️ |

| UV-stability | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️ |

| Flame retardancy | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️⭐️ |

| Full insulated | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️⭐️ | ⭐️ |

| Surface quality | ⭐️⭐️⭐️⭐️ | ⭐️⭐️ | ⭐️⭐️⭐️⭐️ |

| Weight | ⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️ | ⭐️⭐️ |

| Thermal conductivity | ⭐️ | ⭐️ | ⭐️⭐️⭐️⭐️ |

| Special colours | ⭐️ | ⭐️⭐️ | ⭐️⭐️⭐️⭐️ |

| Mechanical processing | ⭐️⭐️⭐️⭐️ | ⭐️⭐️ | ⭐️⭐️⭐️⭐️ |